Other Machinery

Agrometal-Food-Tech Kft. is not only involved in the construction of complete plants but is also a manufacturer of various other equipment. These include stainless steel tanks, robotic production lines, equipment for coated dessert production lines (melting tanks, dipping lines, and cooling tunnels), refrigeration technology machines, pasteurizers, water purification machines, and whey processing systems. In the fields of crop cultivation and environmental protection, its bacteria cultivation equipment supports the production of soil fertilizers and oil-eating bacteria.

Design and manufacture of custom stainless steel containers

The Agrometál group has been manufacturing and installing stainless steel containers for 35 years, in more than 35 countries all over the world from the Kamchatka Peninsula to the Middle East to Paris.

The containers, ranging from 300 litres to anything as large 100,000 litres, as are manufactured in the group’s manufacturing halls with cutting edge technologies, under strict quality control (ISO, PED, TÜV).

Production is supported by longitudinal, circumference and orbital welding robots, and even laser welding robots used in the production of cooling jackets. In terms of equipment, a container may be ordered with insulation, CIP washing head, neck section, mixing apparatus, heating or cooling jacket, heating insert and lightning arrester, even in pressurised versions.

The containers, ranging from 300 litres to anything as large 100,000 litres, as are manufactured in the group’s manufacturing halls with cutting edge technologies, under strict quality control (ISO, PED, TÜV).

Production is supported by longitudinal, circumference and orbital welding robots, and even laser welding robots used in the production of cooling jackets. In terms of equipment, a container may be ordered with insulation, CIP washing head, neck section, mixing apparatus, heating or cooling jacket, heating insert and lightning arrester, even in pressurised versions.

Design and construction, and commissioning of robotised production lines

Agrometál has, since 2021, been offering robotics solutions as well. These complex solutions comprise, for the most part, collaborative and industrial robots developed by the Japanese company Omron, and Agrometál’s automated systems. Robots may be a solution to labour shortage challenges and although they come at a high initial cost, the investment may already pay off in the medium term. In addition to enabling safer and more economical production, robots can even be operated in 3 shifts

Design, manufacture and commissioning of a chocolate-covered curd dessert production line and delivery of training for its operation

Agrometál is proud of the chocolate-coated curd snack (“túró rudi”) manufacturing lines it has designed and built, as a considerable proportion of the curd dessert products sold in the domestic and international markets is produced by manufacturing lines put in place by the Company. Agrometál technologies are available from the acceptance of delivery of raw milk, therefore not only certain component units but complete manufacturing lines can be ordered. Such lines have already been installed in both nitrogen and air cooled versions. Curd dessert manufacturing lines constructed by Agrometál are in operation in Hungary, Austria, Russia, Kazakhstan and Tajikistan. Depending on the chocolate coating and the applied technology, curd dessert has a shelf-life of up to 30-60 days after the date of manufacture if stored below 10 C, and can be stored much longer deep frozen.

Cooling technology

A peripheral but indispensable technology of food and beverage production, cooling technology (air cooling, direct evaporative cooling, water cooling, glycol cooling) is one of the most important divisions of Agrometal-Food-Tech Kft. The basic equipment of economical cold energy production and storage include specially designed and constructed cooling units and ice batteries. A wide variety of user requirements for technological heating and cooling functions are satisfied by our laminar and tubular heat exchangers.

Water purifier – Clean waterz

The modular equipment is suitable for purifying water from drilled wells or mains water without the use of chemicals, with the help of regenerable adsorbents. It produces clean and potable drinking water by removing arsenic, iron, manganese, ammonia and iodine. With solar panel support the equipment independently supplies clean water in times of emergency. Thanks to its dimensions (1200mm*800mm*2000mm) it is easy to move and install. It can produce 1000-6000 litres of clean water per day. The backwash water output of the operation can be discharged into the public sewer or channelled elsewhere.

Milk vodka plant

Lactose-based ethanol production from milk whey.

Whey is a by-product of cheese production. The technology developed by Agrometál enables the production of ethanol through distilling the product of the fermentation of condensed lactose derived from whey.

The by-product of the fermentation product can be used as livestock feed and the water resulting from the distilling process can be discharged into the sewer after the removal of its yeast content or used as technological water after RO (reversed osmosis) filtering. Some 470 litres of vodka, 170 kg yoghurt and 1,000 kg cheese can be produced from 10,000 litres of milk. The first such plant was successfully commissioned by Agrometál in Mongolia, much to the delight of local residents.

Whey is a by-product of cheese production. The technology developed by Agrometál enables the production of ethanol through distilling the product of the fermentation of condensed lactose derived from whey.

The by-product of the fermentation product can be used as livestock feed and the water resulting from the distilling process can be discharged into the sewer after the removal of its yeast content or used as technological water after RO (reversed osmosis) filtering. Some 470 litres of vodka, 170 kg yoghurt and 1,000 kg cheese can be produced from 10,000 litres of milk. The first such plant was successfully commissioned by Agrometál in Mongolia, much to the delight of local residents.

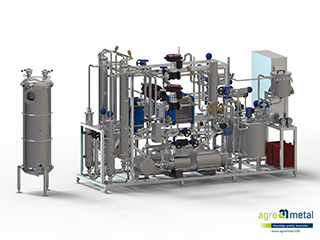

Design, construction and commissioning of a chemical plant

Turnkey chemical plant. Agrometál-Food-Tech Kft. is a general contractor and manufacturer of small and medium-sized chemical plants. The engineering, design and construction of a chemical plant poses a variety of challenges, but Agrometál's experienced and highly qualified specialists are able to effectively address such issues and ensure successful completion of projects. The necessary facilities, including the technological pipelines, the processing and mixing tanks, the service walkways and other piece of equipment, are produced at the Company’s 5 manufacturing halls. Such a plant is constructed on the basis of the customer’s ideas, in cooperation with the design engineer, under the tightest quality control. Products that can be manufactured on Agrometál’s manufacturing lines: plant protection products, antifreeze, and window cleaning fluids etc.

Infusion Pasteuriser (using steam)

The steam heat treatment equipment developed and manufactured by AGROMETAL is suitable for the heat treatment of a variety of fluids used or produced in the food industry, including fruit juices, milk, whey, condensed milk etc. Infusion sterilisation is a heat treatment technology which, unlike conventional pasteurisation, ensures complete sterilisation and, consequently, a long shelf life, without compromising the taste of the product. The steam technology may be an excellent solution for anyone wishing to improve the quality and taste, extend the shelf life and enhance the safety of their pasteurised products. In the case of condensed milk products pulverisation is a technology for manufacturing highly safe products, including infant food. The processing capacities of the models of the product family range – depending on the material to be processed – between 1,500 and 15,000 litres per hour, even in 8-10 hour continues operation cycles. The equipment operates automatically and only needs supervision. Its configuration and instrumentation is in conformity to the current EU norms. Particular attention was paid in the development, design and manufacture of the equipment to controllability and to conformity with the applicable food hygiene regulations.

Design, manufacture, commissioning and enhancement of a cosmetics plant

Agrometál is also a partner in the cosmetics industry. Besides professional quality food processing machinery, it also manufactures and distributes equipment for the production of fine cosmetic products; it has designed and built production lines and other equipment for a number of cosmetics manufacturers, and when required, it undertakes to design and construct compete plants. Some of the products on the market (shower gels, hair conditioners, hand creams, massage creams, shampoos, etc.) are produced in plants constructed by Agrometál.

Construction of a ricotta production facility

Ricotta előállítása innovatív technológiával:

Production of ricotta using some innovative technology:

It was in cooperation with professional organisations that Agrometál developed a continuous ricotta production line, a unique facility in the food machinery industry.

Together with the required technology, it offers a system for the recovery of whey proteins in continuous operation with an energy-saving process based on the isoelectric denaturation of whey proteins and the associated thermal coagulation. Agrometál’s equipment won the Hungarian Product Grand Prize in 2007.

Production of ricotta using some innovative technology:

It was in cooperation with professional organisations that Agrometál developed a continuous ricotta production line, a unique facility in the food machinery industry.

Together with the required technology, it offers a system for the recovery of whey proteins in continuous operation with an energy-saving process based on the isoelectric denaturation of whey proteins and the associated thermal coagulation. Agrometál’s equipment won the Hungarian Product Grand Prize in 2007.

Design, production and commissioning of an industrial ice cream plant

Agrometál manufactures and distributes equipment for the production of ice cream on an industrial scale. As such, it can provide all of the equipment and machinery required by the customer from the reception of raw milk to the packaging of the finished ice cream, including a milk reception unit, a homogeniser, pasteuriser, storage tanks (milk, vegetable oil, melted fat, water, sugar, etc.), mixing unit (disaggregator), refrigeration equipment, packaging machines, etc. Agrometál has already built a number of ice cream plants, ranging from plants suitable for the production of traditional ice cream specialities to plants requiring special equipment for the production of small 3-5 mm deep-frozen ice cream balls. The latter ice cream speciality is particularly eye-catching with its interesting shape, rich colours and very delicate flavour.

Industrial equipment and production lines for vegan food production

Agrometál distributes and manufactures production lines and equipment for the production of vegan products. The Company’s range includes vessels, liquid pasteurisers, pant fat melters, vacuum cutters, shredders, powder mixers and a variety of insulated, heated and mixer tanks, tanks with mobile CIP connection and tanks with steam generators and pressure tanks. Such equipment can be used in producing a variety of vegan foods such as vegan cheeses and yogurts, vegan juices, plant seeds, dried grains, dried ingredients, vegan muesli, vegan vegetable bars and bars, vegan chestnut paste, vegan sauces and sandwich spreads, chocolates, meringues, supplements and drinks.

Fermenters, Bioreactors

The term "fermenters" refers to equipment that controls fermentation processes. Fermentation is a biochemical process in which microorganisms, such as yeasts or bacteria, break down organic materials under aerobic or anaerobic conditions, meaning with or without oxygen. Various products can be produced during this process, such as alcohol, acids, or gases. The products of Agrometal's fermenters to date include: biogas, medicinal herbs, sourdough, tocopherol, ethanol (beer, wine, pálinka, vodka), yogurt, and kefir.