Beer / Equipment

The main elements of turn key catering or micro workshops manufactured by Agrometal-Food-Tech Ltd are the open-view brewery, fermentation equipment and refrigeration equipment.

The main elements of the industrial plants consist of the malt mill equipment, brew house, fermentation equipment, yeast treatment and refrigerating unit.

Our Mini workshops can be extended in a modular system and in order to have a simpler way of installation these can be manufactured in a form of containers.

It is worth learning the other supplementary units of our complete brewery machinery. These are the following:

Universal mashing tub, universal surrogate - finding, filter tub, universal wort boiling and whirlpool tun, wort chiller with plate aerator, CIP station, yeast propagation and processing plant, yeast processing equipment, beer filtration system, beer pasteaur equipment, complete finished product bottling equipment, tunnel pasteaur, production process automation, water treatment plant, steam boiler.

|

Wet malt millIt is a high–performance, reliably operated wet malt mill to soak and grind malt (wet milling).

Applying the latest technology.

The effect of regulated soaking can be seen not only in the high extract content but in the better composition of the beer as well. The system operates in a fully automatic mode.

|

|

Universal surrogate – finding tubThe universal surrogate – finding tub makes it possible to process surrogate and malt substitutes and this ensures the wider product line and the wiser range of flavours of wort produced.

|

|

Filter tubThe high yield of wort filtering can be ensured with the help of the high efficiency filter tub being controlled automatically. This kind of advanced filtering technology solves the problems of wort filtration and can provide high-purity wort quickly.

|

|

Wort boiling whirlpool tunThe advanced universal – wort boiling whirlpool tun:

The system operates with the installment of an outdoor heater:

With the exclusion of the wort having contact with air.

The method – recommended by AgrometalFood-Tech Ltd - of beer boiling with installing and external boiler is one of the most up-to-date methods of wort boiling.

|

|

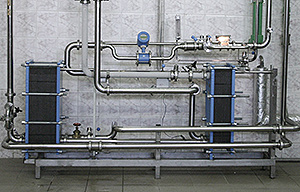

Wort chiller with plate aeratorThe basis of good fermentation is the intensive wort cooling and effective aeration.

Refroidisseur de moût à plaques, avec aérateur, complet

La rapidité du refroidissement du moût est une garantie contre l’acidification et la décoloration de ce dernier.

La diminution de l’arôme de houblon et celle de son goût amer viennent de l’enrichissement en air du moût.

|

|

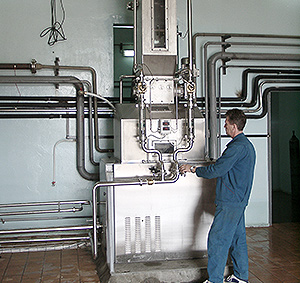

CIP stationThe guarantee of quality is purity. The durability and long-lasting characteristic of high quality standards of beer (such as taste, aroma, foam resistance, transparency) can be ensured with the operation of a washing and disinfecting CIP-station that does not interfere with the pipelines.

(in the photos above a three-storey brew house CIP station can be seen, below a 4 m3 tank of hotly in production environment)

|

|

Yeast propagation and processing equipmentUnit

|

|

Complete yeast propagation and processing equipmentModern design equipment, a high degree of sterility–it is designed to propagate pure yeast culture in any quantity. The applied operation provides the production of biologically high purity yeast.

The equipment provides a more efficient use of more generations of yeast.

|

|

CKT tanksOur company produces and supplies CKT – fermentation tanks of different sizes. The smallest one has a useful capacity of 1 m³, the biggest of 100 m³.

The fermenters with automated systems have proved to be operated reliably under different weather conditions.

|

|

Beer Filtration SystemThe two-stage beer filtration system works in an automatic mode. With its use the long shelf life and retention of taste characteristics of beer can be provided.

|

|

Beer pasteurTo improve the biological stability of beer during pasteurization is one of the methods to lengthen the shelf life of beer. It is a fully automated beer pasteaur machinery operating in 24/7.

Benefits:

Simple operation, advanced design, economical operation and high – quality finished products.

Complete finished product finishing equipment

Complete finished product finishing equipment.

The finishing line includes washing bottles, bottling the finished product, labeling the package, and providing shrink packaging.

|

|

Tunnel pasteaurThe most reliable method to provide shelf life of bottled beer is beer pasteauring in the automatic tunnel pasteaur system. It is modern, comfortable, aesthetical and simple.

|

|

Tunnel de pasteurisationLa

|

|

Process automationThe automation of the production process minimizes the proportion of manual labor, makes the machinery aesthetic and easy to operate, the production rooms will have a high standard of cleanliness.

|

|

Water Treatment EquipmentThe key to the success of beer production is crystal-clear soft drinking water meeting all the microbiological and chemical requirements. These requirements are ensured by the complex water treatment systems.

|

|

Steam-boilerHigh operational safety, economical, fully automated steam boiler to provide steam needed for the brewery technology processes, having an automatic block burner powered by gas, fluid gas or diesel.

|

|

Mini breweryAlways fresh beer.

Wide range of products.

Aesthetic design.

Spectacular – to take part in the brewery technology operating in a restaurant, pub –

Refrigetar or with ice battery

It is exceptionally reliable and in a fully automated mode it is able to produce the cooling energy with its ice battery that is necessary for brewery.

It can be delivered in either air - and water cooling models.

|

|

Refroidisseur à accumulateur de glaceParticulièrement

|